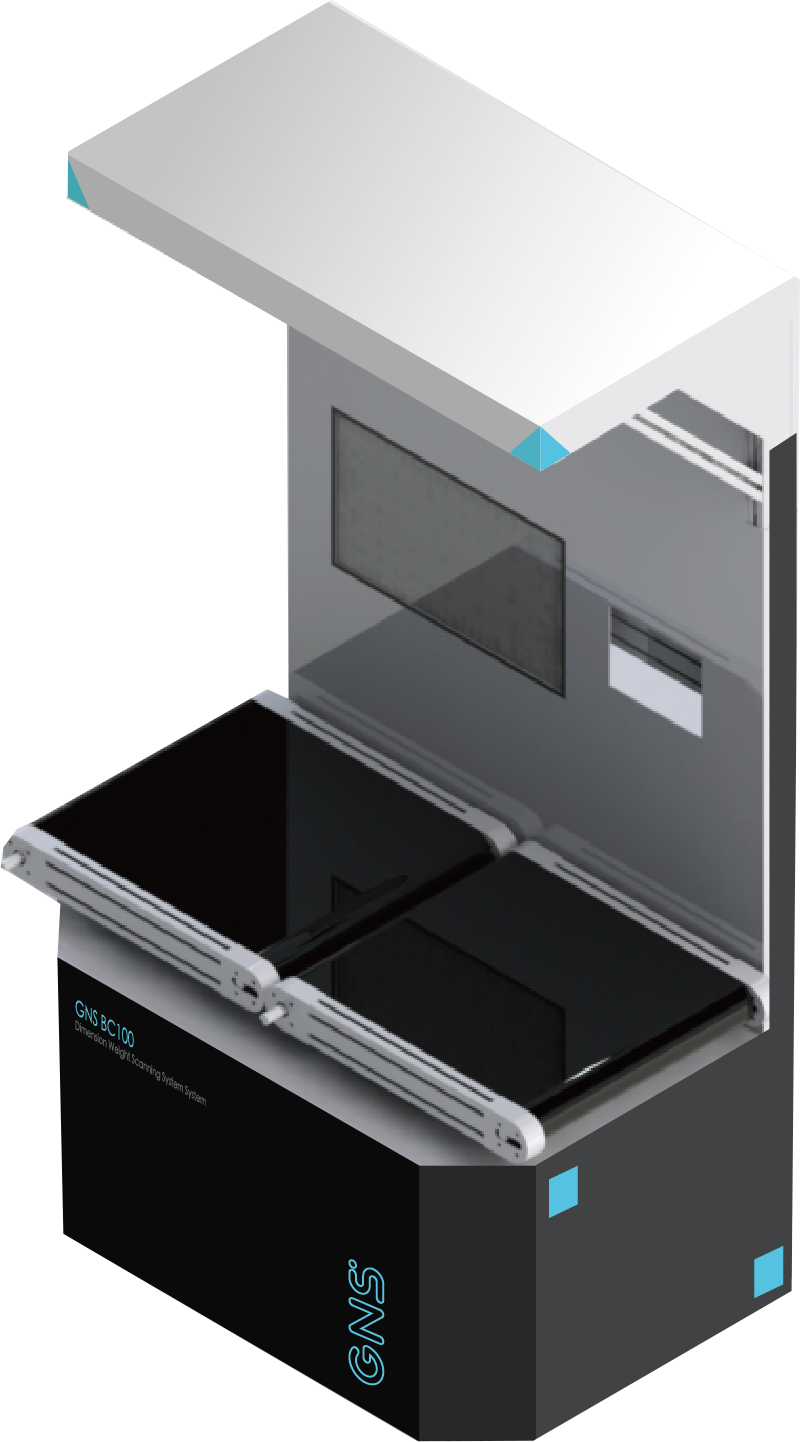

Logistic Automation SolutionScan cargo length, width, height/barcode/weight instantly

Automatically input the invoice and upload it to the backend cloud system

Make the highly repetitive and labor-intensive cargo measurement work easy with high efficientAUTOMATIC SCANNING BY SINGLE MACHINE

Cargo measurement

Scan barcode

Data upload

GNS Technology LimitedFour larger container terminals and warehouses

already using GNS DIMENSION WEIGHT SCANNING SYSTEM in daily operation

Every month, more than 100,000 cargo

were automated measured by GNS DIMENSION WEIGHT SCANNING SYSTEM

Highly intelligent sensors with industrial-grade quality ensure its durability

It has various functions to improve measurement accuracy and reading accuracy. A variety of measurement sensors can be selected to suit different solutions and requirements. Fully compatible with API and RESTFUL software, it is convenient to connect data to the backend system.

Real-time system monitoring system prevents incorrect data from being entered

System status is updated and displayed on the user interface in real time that prevent incorrect data from being entered due to system or equipment abnormalities.

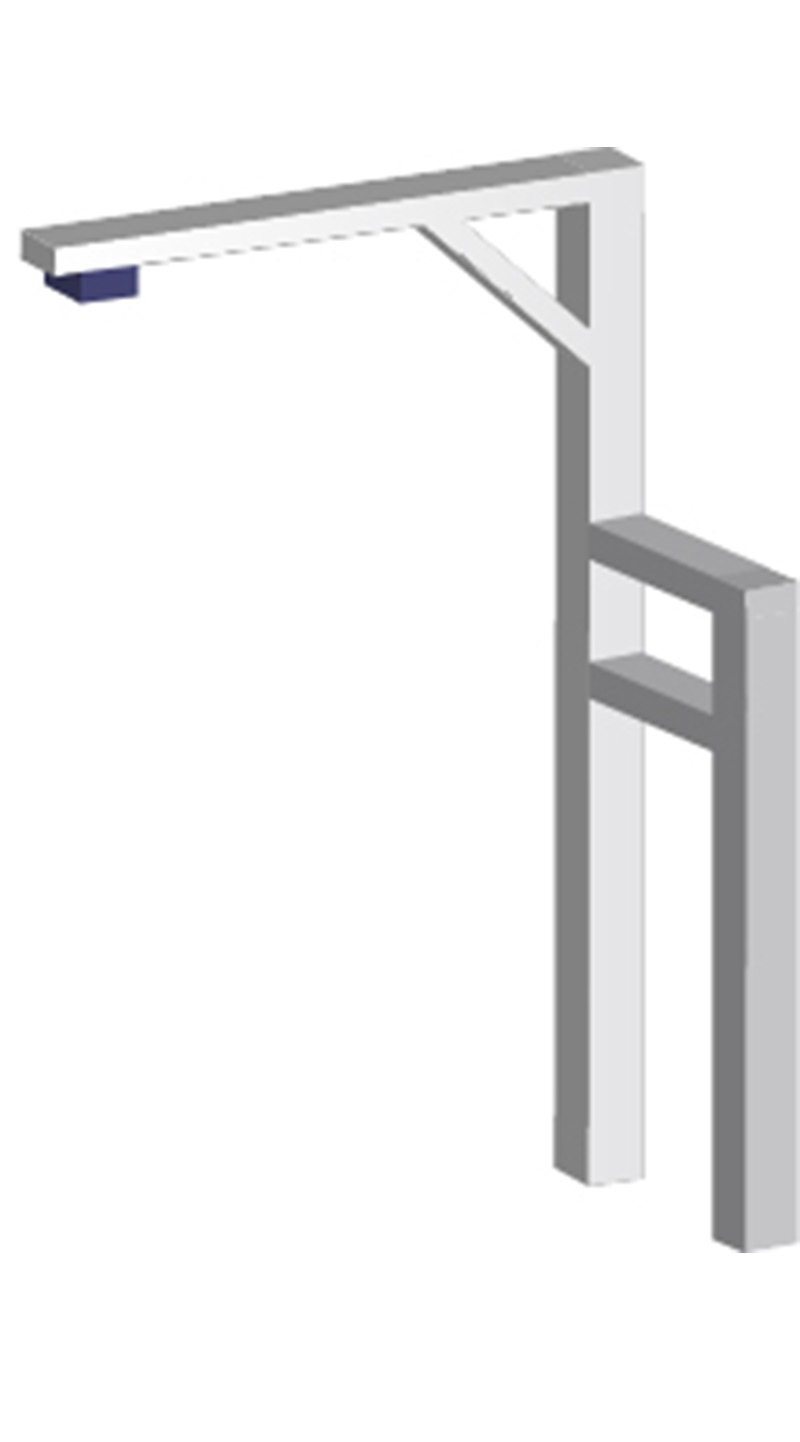

Flexible equipment for design exclusive automation solutions

We understand that different companies have different warehouse sizes, working procedures and models. Therefore, we provide different measurement system solutions to match the most suitable and cost-effective solution for each small and medium-sized enterprise.