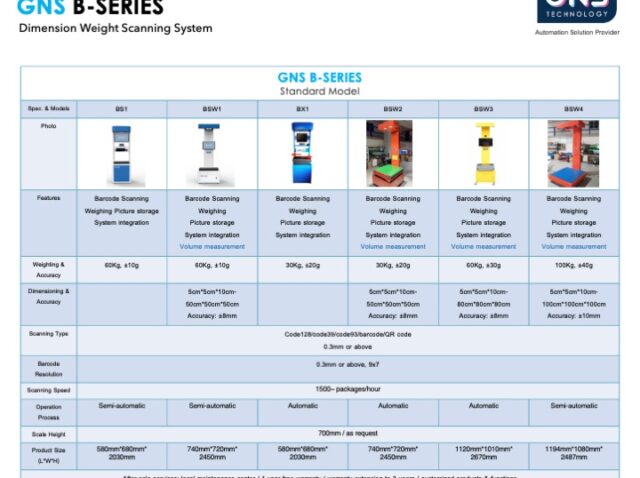

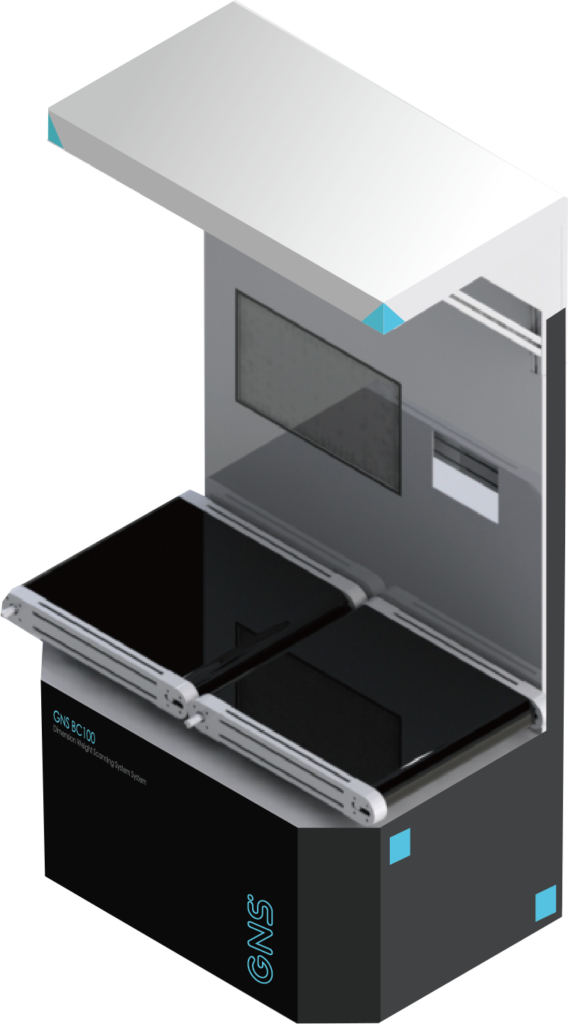

Dimension Weight Scanning SystemGNS-B

SERIES

Special for small and medium-sized cargo

Logistics automation system with automated measurement and instant cloud upload of electronic manifest

Integrate and simplify transportation steps to improve transportation efficiency

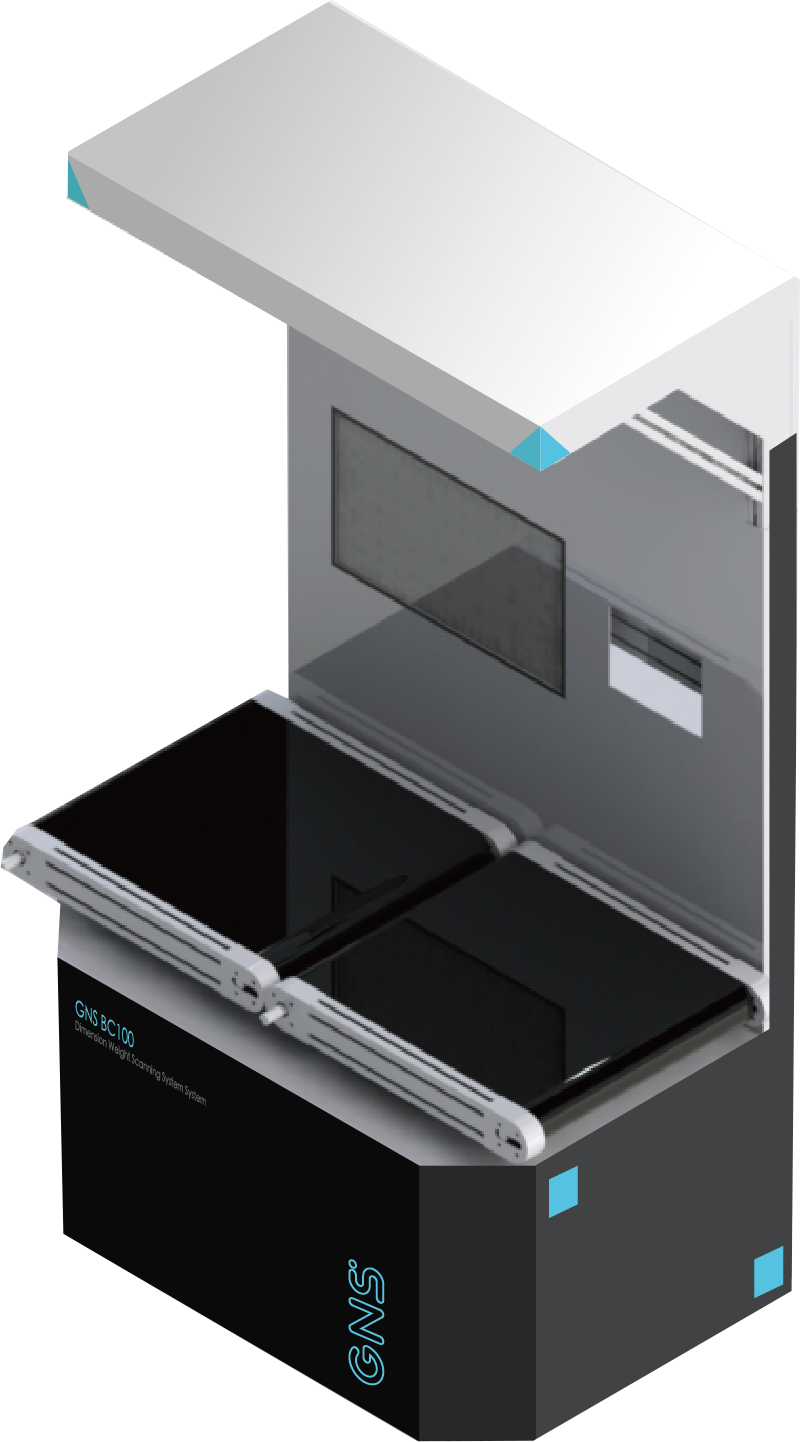

AUTOMATIC SCANNING BY SINGLE MACHINE

There is no need to separate processing at different locations, which could help to save warehouse space and manpower.

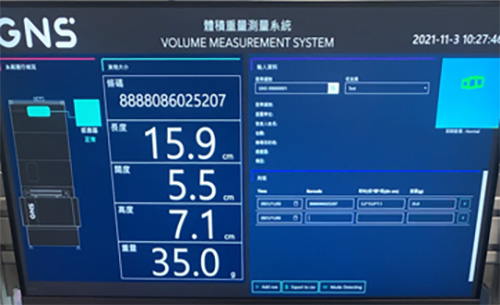

Cargo volume and weight measurement

Scan barcode

Real-time cloud data upload

Mechanical configuration overview

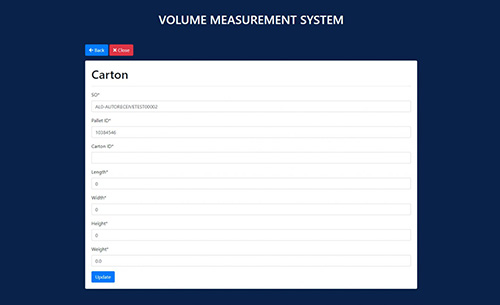

3 simple steps to complete measurement and enter cargo order

Invoices are instantly uploaded to the backend system to facilitate inventory management.

Using world-class measuring instruments to ensure high accuracy, high efficiency and high readable rate

Sensors use laser scanning technology and highly intelligent systemsLASER SENSOR WITH HIGH INTELLIGENT

Create 3D images of objects

Measuring box/irregular shapes with as low as 1cm deviation

Not affected by light/temperature

Detect barcodes as low as 0.2mm resolutions

It facilitates back-office to arrange more accurate transportation planning to obtain maximum profit at the minimum cost.

Cargo dimension scanner

3D laser scanning technology

Scan cargo in straight lines with laser to simultaneously create 3D images

The measurement deviation can be as small as 0.5mm

To measure boxes and irregular shapes more accurately

Can complete the measurement step of cargo dimension in second

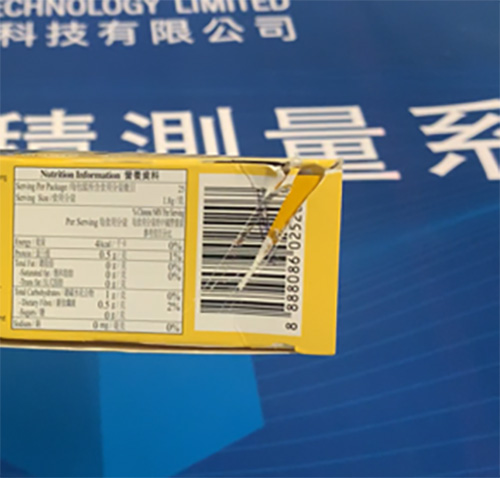

Laser barcode scanner

Laser light guidance technology

A mirror is used to guide the laser light to the sensed barcode surface. Combined with the intelligent correction function, it can detect barcodes as low as 0.2mm. The performance is not affected by light. Even if the barcode surface is reflective/uneven and severely damaged, the data reading accuracy is still as high as 99%.

Fully customized service

The design best fits the business model

Local professional team to serve you

Design a seamless user experience

Mechanical and electronic engineers

Software Development Engineer

Long-term maintenance services

Professional technicians can provide on-site maintenance within one working day at the earliest after making an appointment. We also provide disassembly and reassembly services to facilitate warehouse relocation or layout changes.